清空记录

历史记录

取消

清空记录

历史记录

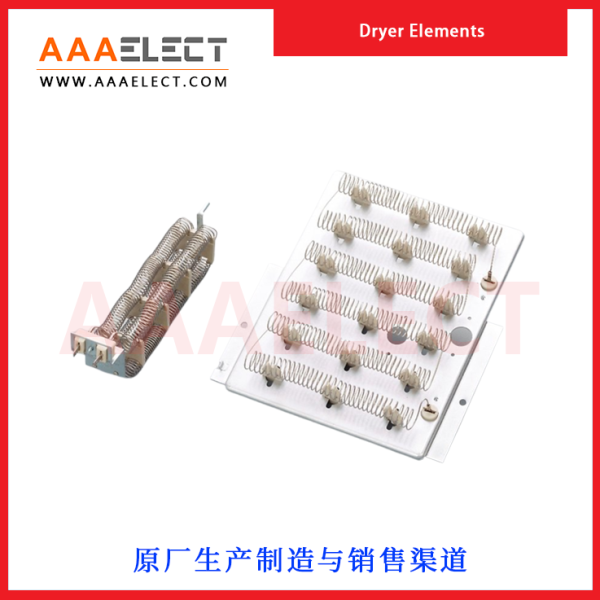

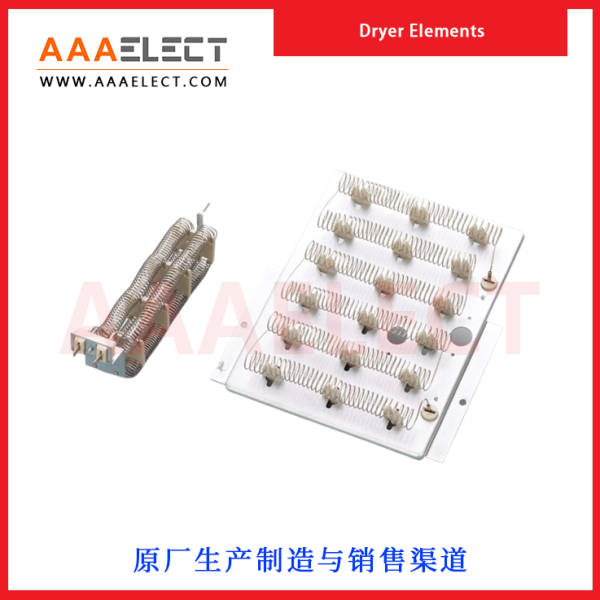

Dryer Elements

We are pleased to offer the most reliable dryer heating elements at the best value available for the Home Appliance market including our line of laundry elements which provide the highest performing and safest solution on the market.

For the laundry elements these fall into our open coil group of heaters. This is where the heated wire or open coil is exposed to open air versus being encapsulated inside the tube with our tubular group of heaters. In order to provide heat with the heated wire exposed to open air there are several key things that need to be provided.

First is the frame or wire support structure used to mount the components to secure the heated wire. Our facility is vertically integrated with the capability for metal forming, stamping, and cutting to supply our production line with metal structure components. Our default material used in galvanized steel for our open coil frames however other materials are available upon request.

Once the frame structure is complete the next component is the isolation supports that are used to touch and securely hold the heated wire during electrical operation. The isolation supports are held in place by the frame structure. Our isolation supports are made from ceramic materials designed to withstand the high temperatures generated from the heated wire. The shape of our ceramics resembles a “ram’s horn” shape.

The last item needed to complete the open coil heater assembly is the heated wire. The material that we use for the heated wire is a Nickel Chromium alloy comprised of 60% Nickel. This alloy structure provides the hot strength needed during electrical operation. Hot strength is the ability of the heated wire to conduct the electricity, provide the heat required in the form of wattage, and at the same time not droop or sag to touch either another heated wire in the circuit or part of the metal frame structure.

The electrical connections that are available include a quick connect type terminal, a hardwired connection with threaded terminals, or lead wires with either stripped ends or pre-installed crimped electrical terminals.

In addition, we offer replacement laundry elements that can be ordered for a just like fit solution for older elements that need updating. Our replacements include the complete assembly with the thermostat, the complete assembly without the thermostat, or just the heated wire itself in a plastic bag that the user can re-string on the ceramic insulators.

Backer-Springfield is a manufacturer of high-quality heating products and, as such, we are only setup to sell to resellers and O.E.M. manufacturers. We are unable to fulfill requests direct from consumers. If you are a consumer seeking a replacement element for your appliance, please contact the manufacturer of your appliance or your local professional service technician for information on the required heating element(s).

Dryer Elements

We are pleased to offer the most reliable dryer heating elements at the best value available for the Home Appliance market including our line of laundry elements which provide the highest performing and safest solution on the market.

For the laundry elements these fall into our open coil group of heaters. This is where the heated wire or open coil is exposed to open air versus being encapsulated inside the tube with our tubular group of heaters. In order to provide heat with the heated wire exposed to open air there are several key things that need to be provided.

First is the frame or wire support structure used to mount the components to secure the heated wire. Our facility is vertically integrated with the capability for metal forming, stamping, and cutting to supply our production line with metal structure components. Our default material used in galvanized steel for our open coil frames however other materials are available upon request.

Once the frame structure is complete the next component is the isolation supports that are used to touch and securely hold the heated wire during electrical operation. The isolation supports are held in place by the frame structure. Our isolation supports are made from ceramic materials designed to withstand the high temperatures generated from the heated wire. The shape of our ceramics resembles a “ram’s horn” shape.

The last item needed to complete the open coil heater assembly is the heated wire. The material that we use for the heated wire is a Nickel Chromium alloy comprised of 60% Nickel. This alloy structure provides the hot strength needed during electrical operation. Hot strength is the ability of the heated wire to conduct the electricity, provide the heat required in the form of wattage, and at the same time not droop or sag to touch either another heated wire in the circuit or part of the metal frame structure.

The electrical connections that are available include a quick connect type terminal, a hardwired connection with threaded terminals, or lead wires with either stripped ends or pre-installed crimped electrical terminals.

In addition, we offer replacement laundry elements that can be ordered for a just like fit solution for older elements that need updating. Our replacements include the complete assembly with the thermostat, the complete assembly without the thermostat, or just the heated wire itself in a plastic bag that the user can re-string on the ceramic insulators.

Backer-Springfield is a manufacturer of high-quality heating products and, as such, we are only setup to sell to resellers and O.E.M. manufacturers. We are unable to fulfill requests direct from consumers. If you are a consumer seeking a replacement element for your appliance, please contact the manufacturer of your appliance or your local professional service technician for information on the required heating element(s).

浏览器自带分享功能也很好用哦~

浏览器自带分享功能也很好用哦~